Original Material Tungsten Carbide Inserts Snow Plow Plate Cutting Edge for Compact Tractors

Overview Original material Tungsten Carbide Inserts Snow Plow Plate Cutting Edge For Compact Tractors Quick Information

Send your inquiryDESCRIPTION

Basic Info

| After-sales Service | Available |

| Certification | ISO 9001:2015 |

| Standard | DIN |

| Surface Treatment | Sandblasting |

| Manufacturing Process | Powder Metallurgy |

| Material | Tungsten Carbide |

| Delivery Time | 25-28 Days for One Batch |

| Trade Terms | Fob,CIF,DDU,DDP,Fca,etc |

| Free Samples | Available If We Have Stock |

| Customization | More Than Welcome |

| Transport Package | Standard Carton |

| Specification | Standard and Customized |

| Trademark | OSTON or customized logo |

| Origin | Zhuzhou, China |

| Production Capacity | 20 Metric Tons Per Month |

Product Description

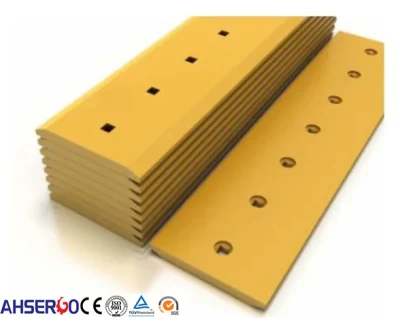

Original material Tungsten Carbide Inserts Snow Plow Plate Cutting Edge For Compact Tractors

Quick Information

| Product name | tungsten carbide snowplow inserts |

| Material | tungsten carbide |

| Grade | YG8C/YG11C/YG13C/YG15C |

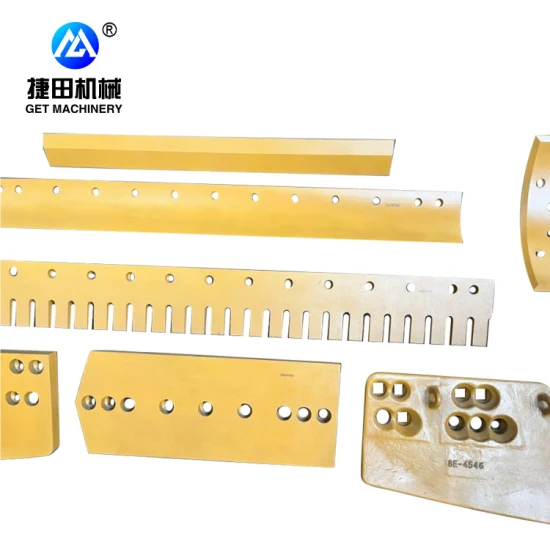

| Size/Type | Ballnosed Inserts,Trapezoid inserts 25 deg,Trapezoid inserts 45 deg,Dome ShapeContact us for detailed drawings and dimensions. |

| Packing | 20-22 kgs/ carton |

| MOQ | 5kgs (sample is also available.) |

| Delivery time | 25-30 days for mass production |

Our Advantages

1. Material: 100% premium virgin raw materials.2. Grade:We developed a custom proprietary grade of tungsten carbide made to specifically endure a tough condition. It is both hard enough to withstand impact, while still provide the absolute maximum in wear protection.3.Production: We have professional advanced production line and inspeciton equipments to ensure high quality products,including HIP sintering furnance,isostatic suppressing,2-dimensional measuring instrument,etc.4.Finishing: We own full line of further carbide finishing equipments including general grinding,centerless grinding,wire cutting,EDMsparkling,polishing,etc,we supply both blank carbide preforms and high precision carbide parts.5.Experienced Sales: Our sales are all with more than 5 years' experience in this field,which will make communication more fluently.

6.Apart from standard sizes, we also offer customization services per your drawings, samples, or required specifications.Detailed Photos

Quality Grade

| Grade | Chemical composition | Density (g/cm3) | Hardness (HRA) | TRS (N/mm2) |

| YG8C | WC92%+Binder8% | 14.6-14.8 | 88.5-89.5 | ≥2500 |

| YG11C | WC89%+Binder11% | 14.4-14.6 | 87.5-88.5 | ≥2600 |

| YG13C | WC87%+Binder13% | 14.1-14.3 | 86.5-87.5 | ≥2700 |

| YG15C | WC85%+Binder15% | 14.0-14.2 | 85.5-86.5 | ≥2900 |

Suitable for

Tungsten carbide snowplow insert is a important part of Snow Plow Blades,the quality stability of carbide inserts is the core for snow plow blades.Tungsten carbide snow plow inserts are placed into milled grooves along the bottom wear surface of the cutting edge giving it unmatched wear resistant properties and making this blade ideal for high speed highway or airport runway plowing,OSTON CARBIDE offers the most complete line of Tungsten Carbide Snowplow insert edges.

Quality Control

1. Material Milling and DesiccationDust-Free Workshop: All staff must wear specified uniforms before entering the workshop.2. Isostatic Suppressing for carbide rodsMachinery Automation:Automatic manipulators are installed for all of our TPA suppressing facilites,which is more accurate on weight controlling and reduces production cost.3. HIP Sintering Strict rules of operation: All operation need be conducted strictly as process rules.4. Quality checking of trial production.New testing piece: Testing piece must be produced before a new batch of material is used for mass production to ensure the stablequality.5. Grinding and MachiningWe own all facilitess for the whole carbide machining system to ensure the delivery in time,including surface grinding lathe,external grinding lathe,centerless grinding lathe,wire cutting machine,EDM sparkling machine.6. quality checking of finished products.Double Quality Checking: Inspection for semi-finished and finished products are both essential,products with defects will never be shipped.7. Packing and deliverySafe package and delivery: Kraft paper for the first layer,bubble plastic for the second layer,gaps are filled with sponge,We focus on every package detail to ensure that clients receive our goods with good looks and good quality.

About Oston Carbide

Q:Is OSTON CARBIDE producer ?

A:OSTON CARBIDE is a exporting subsidiary for our parent company,which is a manufacturer of tungsten carbide and diamond wheels since 1998,you will get both manufacturing prices and good services here

Q:What kind of products and service could OSTON supply ?

A:OSTON has been specializing in carbide solutions for clints more than 20 countries,which includes design and manufacturing of various carbide parts.

Q: Is there any certification for products of OSTON ?

A: Yes,All products from OSTON have been endorsed with the ISO9001:2015 certification.

Q:Can a drawing be supplied to OSTON for further design ?

A: Yes,we encourage sending as more information as possible,drawing and sketch are welcome for specific quotation,even a sample could be sent to OSTON for further design. Q:When can I get the offer after sending inquiry ?

A:Our sales operates between 9:00 am to 6:00 pm Monday to Friday,Offer is usually supplied within 24 hours after we got your inquiry,if you are urgent to get the price,please call us or send email so that we'll take it as priority.

Q:How long time I need spend on waiting for my goods ?

A:Usual delivery time is 15-18 days after 30% down payment is received,please confirm with us before placing the order if you need urgent turnaround delivery.

Related Products

-

![Square End Dovetail Groove CNC Router Machine Bits for Wood Carbide Cutting Tools]()

Square End Dovetail Groove CNC Router Machine Bits for Wood Carbide Cutting Tools

-

![OEM Precision CNC Machining Food Machinery/Construction Machinery/Engineering Machinery/Crawler/Grader/Hydraulic Motor Spare Parts Aluminum Parts]()

OEM Precision CNC Machining Food Machinery/Construction Machinery/Engineering Machinery/Crawler/Grader/Hydraulic Motor Spare Parts Aluminum Parts

-

![4Cr5MoSiV1 Material Excavator Hydraulic Shear Blade]()

4Cr5MoSiV1 Material Excavator Hydraulic Shear Blade

-

![Factory Price Grader Blade for Caterpillar Parts Excavator Front Tractor Grader Blade]()

Factory Price Grader Blade for Caterpillar Parts Excavator Front Tractor Grader Blade